safety valve|Safety valve installation location and requirements

Before installing the safety valve to the protected equipment or before installation, the user must re-adjust at the installation site to ensure that the set pressure value of the safety valve meets the requirements. Do you know where the safety valve is installed?

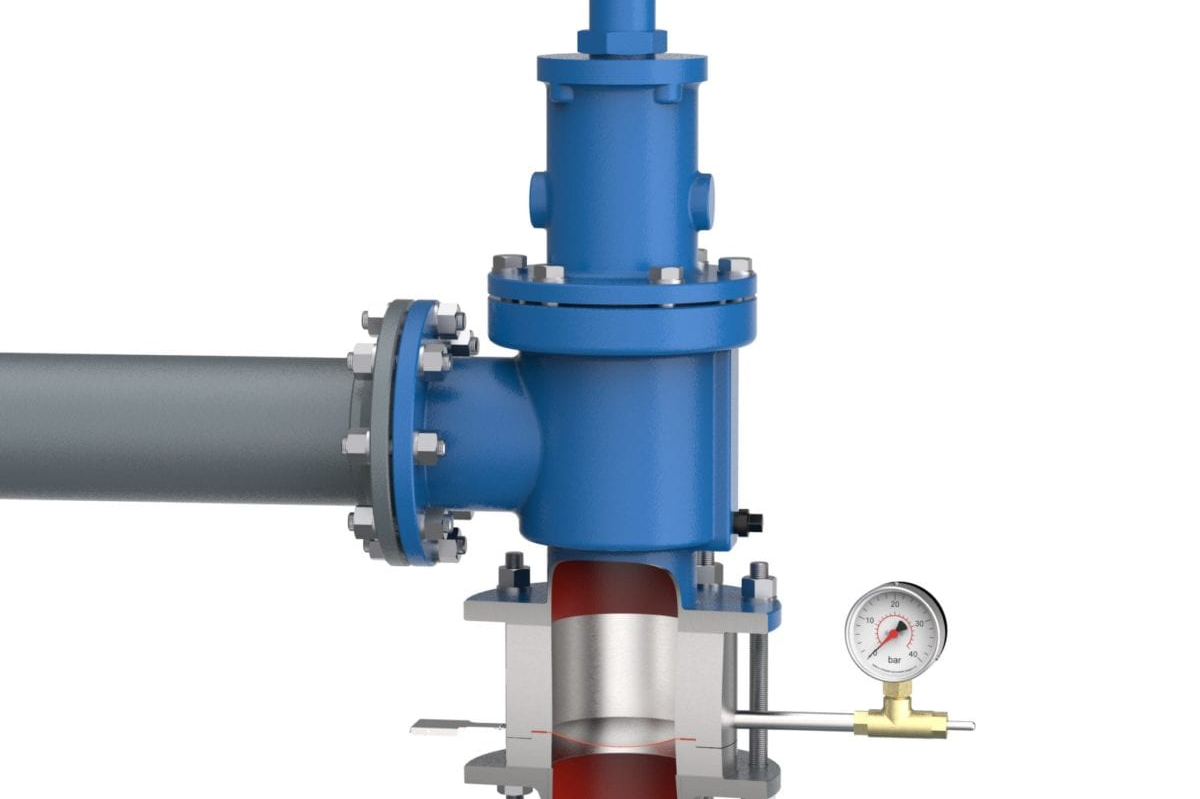

1) Install vertically upwards.

2) The installation location should be as close as possible to the protected equipment or pipeline. Install in a place that is easy to repair and adjust, with enough space around.

3) The safety valve of the pressure vessel is installed in the gas phase space above the liquid level of the vessel body, or it can be installed on the pipe whose connection point is located in the gas phase space of the pressure vessel.

4) For containers and equipment containing flammable, toxic, and viscous media, a shut-off valve can be installed in front of the safety valve, but the flow area of the shut-off valve shall not be less than the minimum flow area of the safety valve, and a lead seal shall be installed to ensure the shut-off The valve is fully open and normally open.

5) The safety valve should be installed in the reverse direction of the stop valve to reduce the influence of the valve's gravity and avoid stress fatigue and discharge vibration fatigue.

6) For safety valves that may be blocked or corroded by materials, a rupture disc is installed in front of its inlet, and an inspection valve is installed between the safety valve and the rupture disc, and the inlet pipe is back-purged, heated or insulated. And other anti-blocking measures.

7) The safety valve installed on the pipeline should be installed in a place where the fluid pressure is relatively stable and there is a certain distance from the source of fluctuations. It cannot be installed in a dead corner of a horizontal pipeline.

8) For liquid medium pipelines, heat exchangers or pressure vessels, when the valve is closed, thermal expansion may occur, causing the problem of high pressure, the safety valve can be installed horizontally to directly discharge the liquid downward.

9) For emergency air discharge, the nozzle should be flat, not sharp, and free of burrs to prevent electrostatic discharge.

10) The safety valve installation point should not allow the safety valve to withstand excessive back pressure and should be within the specified allowable range.

11) The valve body of the safety valve should be supported and stabilized.

12) The medium is a container with extremely and highly hazardous or flammable and explosive medium, and the discharge port of the safety valve should be led to a safe place and handled properly. If two or more safety valves share one discharge pipe, the cross-sectional area of the discharge pipe should not be less than the sum of the cross-sectional areas of all safety valve outlets, but oxygen or combustible gas and other two gases that can chemically react with each other cannot share one. Root discharge pipe.

13). .