Plus type fully equipped

CNC machine tools ,large vertical lathes, drill press, milling lathe grinding machine , Welding machine , separate metal working workshops and many general machine tool etc.

Multiple tests

Material analysis, PMI Material analysis. Chemical analysis. Low temperature test, Tensile Test ,Impact test, Hardness test. Wall thickness test, roughness test. Torque test. NDT Inspection (MT,PT,UT,RT). HIC test ,SSC test . Intercrystalline corrosion Test ,Uniform corrosion Test.

Passed ISO certification

The company is the first one to pass ISO 9001(2008),ISO 14001 ,OHAS 18001 international quality system certificate, China pressure pipe safety registration certificate (AZ), European Union safety registration certificate (CE0036), and American Petroleum Institute Certificate (API 6D) and (API607) .

Industry Association Member

We are one of the member unit of China Valve Association as well as China Gas Association, member unit of first class supplying network of CNPC and member unit of fittings supplying network of State Power Corporation.

Related Products

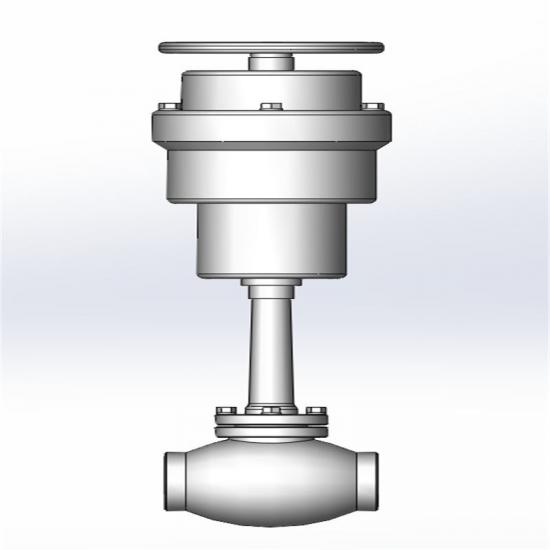

More items about cryogenic valve

We Have The Best Solutions for Your Business

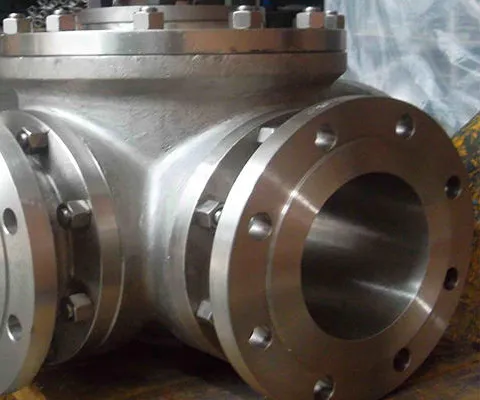

EDVC VALVE CO.,LTD.is a specialized in valve manufacturing enterprise with more than 15 years of history.We main produce Top Entry Ball Valve, Fully Welded Ball Valve, Arc Valve, Aluminum Bronze Valve, Automatic Recirculation Valve, Orbit Ball Valve, Safety Valve, Globe Valve, Tilting Disc Check Valve and Rising Stem Ball Valve etc.

The products have been exported to Austria, France, Germany, United Kingdom ,America, Middle East and Asia, Africa . areas and countries. Moreover, the products are widely used in the fields of oil & gas, Oil refinery, Petrochemical,power station ,Sewage treatment, pharmacy, Paper mills, pipeline industry , mining industry , chemical industry and environmental protection.

We are a professional manufacturer of valves in China, with the aim of "providing the first class products and services". On behalf of all of the members at EDVC Valve, we thank you for the opportunity to earn your business.

The structure design of the drip plate of the cryogenic valve

Since the transmission in the valve is a low-temperature medium, in order to avoid or reduce the transmission of medium temperature to the valve stem and the filling material at the upper end, and prevent these materials from failing due to freezing, a drip plate structure can be added to the valve.

Material selection for cryogenic valves

The working medium of cryogenic valves is not only low in temperature, but most of them are toxic, flammable, explosive, and highly permeable, so it determines many special requirements for valve materials. The mechanical properties of steel at low temperatures are different from those at room temperature. In addition to strength, the most important index of low-temperature steel is its low-temperature impact toughness.

Installation requirements for cryogenic valve

Because of the special structure of the cryogenic valve, the installation of the cryogenic valve also has its special requirements. Because of the structural characteristics of the long-neck bonnet of the cryogenic valve, the direction of the stem of the cryogenic valve must be within a vertical angle of 45 degrees during installation, and installation on vertical pipelines should be avoided as much as possible. Otherwise, the low temperature medium will fill the extended part of the valve cover, causing the valve packing to fail, and will transfer the cold to the valve handle, causing personal injury to the operator. For cryogenic valves with pressure relief structure, when installing the valve, pay special attention to the requirements of the valve pressure relief direction.

Anti-static and fireproof structure design of cryogenic valve

Since cryogenic valves are generally used in flammable and explosive media, anti-static design and fire protection design are particularly important. Loss of cold. Valves with soft seats or soft closing inserts for flammable vapors or liquids should be designed to ensure that the valve body and stem have electrical continuity, and the maximum resistance of the discharge path should not exceed 10Ω. "The design of the fire protection structure is mainly aimed at the problem of medium leakage caused by the drastic temperature change. The design of the fire protection structure is similar to the design requirements of ordinary valves.

Frequently Asked Question

Do you have any question?

The main reason for the internal leakage of the valve is the deformation of the sealing pair in the low temperature state. When the temperature of the medium drops to a phase change of the material, the volume changes, and the sealing surface with high grinding accuracy is warped and deformed, resulting in poor low-temperature sealing.

Valve leakage: First, when the valve and the pipeline are connected by flanges, leakage occurs due to the unsynchronized contraction of gaskets, connecting bolts, and connecting parts at low temperatures. Therefore, the connection method between the valve body and the pipeline can be changed from flange connection to welding structure to avoid low temperature leakage. The second is leakage at the valve stem and packing.

This is because the plasticity and sealing of the low temperature valve packing will become worse as the temperature drops, leakage and icing will occur at the packing, which will affect the low cooling capacity loss, and the valve cover must adopt a long neck structure. The cross-sectional area of the long neck portion should be small, generally cylindrical, and the gap between the inner wall and the valve stem should also be small. In order to reduce the cold transfer upwards. The length of the neck is related to temperature and caliber. The lower the temperature and the larger the caliber, the longer the length.

It must be on the high pressure side. The purpose is to maintain the pressure balance between the upstream and the valve ball flow passage cavity when the ball valve is closed, to prevent the cryogenic liquid in the ball valve cavity from instantaneous vaporization and expansion, causing the valve body to burst.