Plus type fully equipped

CNC machine tools ,large vertical lathes, drill press, milling lathe grinding machine , Welding machine , separate metal working workshops and many general machine tool etc.

Multiple tests

Material analysis, PMI Material analysis. Chemical analysis. Low temperature test, Tensile Test ,Impact test, Hardness test. Wall thickness test, roughness test. Torque test. NDT Inspection (MT,PT,UT,RT). HIC test ,SSC test . Intercrystalline corrosion Test ,Uniform corrosion Test.

Passed ISO certification

The company is the first one to pass ISO 9001(2008),ISO 14001 ,OHAS 18001 international quality system certificate, China pressure pipe safety registration certificate (AZ), European Union safety registration certificate (CE0036), and American Petroleum Institute Certificate (API 6D) and (API607) .

Industry Association Member

We are one of the member unit of China Valve Association as well as China Gas Association, member unit of first class supplying network of CNPC and member unit of fittings supplying network of State Power Corporation.

Related Products

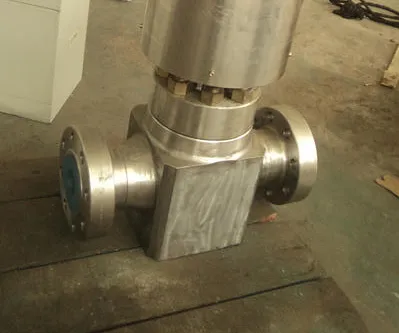

More items about full opening swing check valve

We Have The Best Solutions for Your Business

EDVC VALVE CO.,LTD.is a specialized in valve manufacturing enterprise with more than 15 years of history.We main produce Top Entry Ball Valve, Fully Welded Ball Valve, Arc Valve, Aluminum Bronze Valve, Automatic Recirculation Valve, Orbit Ball Valve, Safety Valve, Globe Valve, Tilting Disc Check Valve and Rising Stem Ball Valve etc.

The products have been exported to Austria, France, Germany, United Kingdom ,America, Middle East and Asia, Africa . areas and countries. Moreover, the products are widely used in the fields of oil & gas, Oil refinery, Petrochemical,power station ,Sewage treatment, pharmacy, Paper mills, pipeline industry , mining industry , chemical industry and environmental protection.

We are a professional manufacturer of valves in China, with the aim of "providing the first class products and services". On behalf of all of the members at EDVC Valve, we thank you for the opportunity to earn your business.

Swing check valve applicable occasions

The swing check valve can be made into a higher working pressure, <PN420, the nominal size can be larger, and it can be DN2000 or above. According to the different materials of the shell and the sealing parts, it can be applied to most working media and most working temperature ranges. The medium is water, steam, gas, corrosive medium, oil, food, etc. The working temperature of the medium is in the range of -196~800℃, and the specific working temperature needs to be confirmed according to the material of the valve body and the internal sealing material.

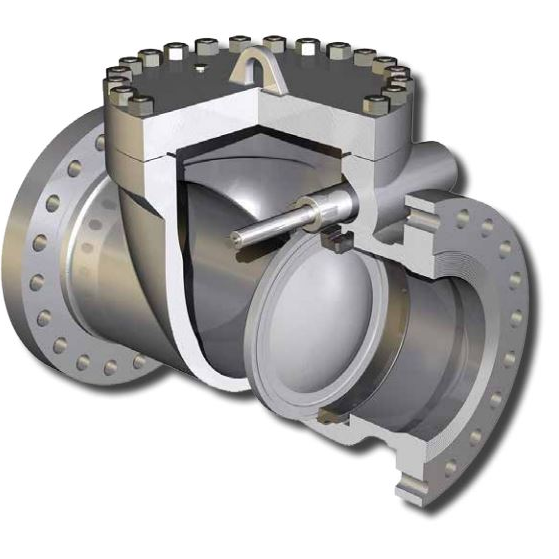

Swing check valve structure

The swing check valve is composed of a valve body, a valve cover, a valve clack and a rocker. The valve clack is in the shape of a disc and rotates around the pin shaft outside the valve seat channel. The channel in the valve is streamlined, and the flow resistance is smaller than the straight-through lift check valve, which is suitable for large-diameter pipelines.

Swing check valve category

Swing check valves are divided into three types, single-leaf type, double-leaf type and multi-half type. These three types are mainly classified according to the valve diameter. The purpose is to prevent the medium from stopping or flowing backwards and weaken the hydraulic shock.

Swing check valve | Prevent valve leakage

The swing check valve adopts a built-in rocker swing structure. All the opening and closing parts of the valve are installed inside the valve body, and do not penetrate the valve body, except for the sealing gasket and sealing ring for the middle flange. , There is no leakage point as a whole, preventing the possibility of valve leakage.

Frequently Asked Question

Do you have any question?

The valve that opens or closes by the force of the flow of the medium to prevent the backflow of the medium is called the non-return valve source. Check valves belong to the category of automatic valves, which are mainly used in pipelines where the medium flows in one direction, and only allow the medium to flow in one direction to prevent accidents. According to the structure, it can be divided into three types: lift check valve, swing check valve and butterfly check valve.

Attention points for installation and use of swing check valve 1. The steam extraction check valve is installed vertically on the horizontal pipeline and is generally in a fully open state. 2. The following work should be done before installation 1) Remove the stuffy cover and foam plate at both ends of the valve channel, clean the inner cavity, and remove the grease; 2) Peel off the grease paper on the surface of the valve disc to remove the grease on the surface of the valve disc; 3. The flow of media must be restricted during installation. 4. The medium passing through the pipeline should not contain hard particles, so as not to damage the sealing surface 5. The valve is inspected and tested one by one before leaving the factory, and the installation unit can directly pressure test or install it.

1. The valve should be stored in a dry and ventilated room to prevent moisture, rain and rust. 2. The opening and closing parts should be in the closing device during storage for monthly transportation, and the following work should be done at the same time: 1) The disc should be fixed in the open position 2) The inner ports at both ends of the diameter are blocked with foam plates, and the ports must be plugged tightly with stuffed caps to prevent dust and rust, keep the channels clean and the end faces flat; 3) Proper packaging protection, anti-vibration and anti-collision for the cylinder part; 4) The valve should be placed steadily, with the pneumatic drive device facing upwards, and should not be squeezed by each other. 3. It should be checked regularly when placed for a long time. Every three months, check the protection status of the dirt and rust on the two channels, the sealing surface, and the welding joint. After wiping the dirt and rust, repaint the anti-rust oil for protection. 8. The overall structure, simple and compact, beautiful appearance 9. Long service life and high reliability