Features

Why Choose EDVC?

Plus type fully equipped

CNC machine tools ,large vertical lathes, drill press, milling lathe grinding machine , Welding machine , separate metal working workshops and many general machine tool etc.

Multiple tests

Material analysis, PMI Material analysis. Chemical analysis. Low temperature test, Tensile Test ,Impact test, Hardness test. Wall thickness test, roughness test. Torque test. NDT Inspection (MT,PT,UT,RT). HIC test ,SSC test . Intercrystalline corrosion Test ,Uniform corrosion Test.

Passed ISO certification

The company is the first one to pass ISO 9001(2008),ISO 14001 ,OHAS 18001 international quality system certificate, China pressure pipe safety registration certificate (AZ), European Union safety registration certificate (CE0036), and American Petroleum Institute Certificate (API 6D) and (API607) .

Industry Association Member

We are one of the member unit of China Valve Association as well as China Gas Association, member unit of first class supplying network of CNPC and member unit of fittings supplying network of State Power Corporation.

We Have The Best Solutions for Your Business

EDVC VALVE CO.,LTD.is a specialized in valve manufacturing enterprise with more than 15 years of history.We main produce Top Entry Ball Valve, Fully Welded Ball Valve, Arc Valve, Aluminum Bronze Valve, Automatic Recirculation Valve, Orbit Ball Valve, Safety Valve, Globe Valve, Tilting Disc Check Valve and Rising Stem Ball Valve etc.

The products have been exported to Austria, France, Germany, United Kingdom ,America, Middle East and Asia, Africa . areas and countries. Moreover, the products are widely used in the fields of oil & gas, Oil refinery, Petrochemical,power station ,Sewage treatment, pharmacy, Paper mills, pipeline industry , mining industry , chemical industry and environmental protection.

We are a professional manufacturer of valves in China, with the aim of "providing the first class products and services". On behalf of all of the members at EDVC Valve, we thank you for the opportunity to earn your business.

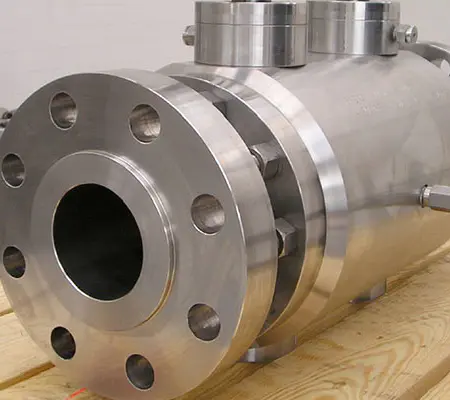

DOUBLE BLOCK & BLEED - FLOATING TYPE

The design of the BFE ball valve is based on the "floating ball" principle, which allows the ball to rotate freely between the spherical seals.

The positive seal is ground on the upstream surface of the ball through the action of fluid pressure, and a constant and uniform contact between the two objects is produced between the downstream steel ball seal and the steel ball.

The steel ball is operated by a sealed spindle with a protruding square end pointed by the control panel-

Dle or optional actuator is connected.

Ball valves used to open/close flow control devices must not be used to throttle fluid flow. The valve should always be closed, fully open or fully closed.

DOUBLE BLOCK & BLEED - TRUNNION TYPE

Trunnion ball valve have a mechanical means of anchoring the ball at the top and the bottom, this design is the standard design applied on larger and higher pressure valves.

Sealing is achieved by spring loaded piston type seats which shut off flow when line pressure acts on the upstream seat. Automatic relief of cavity overpressure is assured due to the trunnion design in case of self relieving seats (BFE standard design). The ball is operated by a sealed spindle to which the operator is attached. Ball valves are intended to be used as on/off flow control devices and are not to be used to throttle fluid flow. The valves should always be either fully open or closed.

Featured Products

Collection about EDVC

Frequently Asked Question

Do you have any question?

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. This feature can be achieved with one single valves complete with a bleed port between the obturators.

DBB means double block and bleed. As per API 6D, a double block-and-bleed ball valve is a single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting or bleeding the cavity between the seating surfaces.

Double block and bleed valves are most commonly used in the oil and gas industry, but can also be helpful in many other industries. It's typically used where bleeding the valve cavity is required, where piping needs isolation for maintenance, or for any of these other scenarios: Prevent product contamination.

Our updates and blog posts

double-block-and-bleed-ball-valve | Can you tell the material of these valves?

{keyword}.Many valves can adapt to a variety of working conditions, but if the valve material is unreasonably selected, the performance and service life of the valve will be greatly reduced.

double-block-and-bleed-ball-valve | Classification of valves

{keyword}.Valves are divided into gate valves, globe valves, butterfly valves, high-pressure valves, low-pressure valves, fluorine-lined valves, safety valves, pressure relief valves

double-block-and-bleed-ball-valve | Valve knowledge: valve terms

{keyword}.General purpose valve,cast iron valve,Cast steel valve,Stainless steel valve,bronze valve, Brass valve ,Forged valve,plastic valve,Ceramic valve,Faucet,Stop cock, stop valve

.jpg?imageView2/1/w/450/h/450/format/webp)