Plus type fully equipped

CNC machine tools ,large vertical lathes, drill press, milling lathe grinding machine , Welding machine , separate metal working workshops and many general machine tool etc.

Multiple tests

Material analysis, PMI Material analysis. Chemical analysis. Low temperature test, Tensile Test ,Impact test, Hardness test. Wall thickness test, roughness test. Torque test. NDT Inspection (MT,PT,UT,RT). HIC test ,SSC test . Intercrystalline corrosion Test ,Uniform corrosion Test.

Passed ISO certification

The company is the first one to pass ISO 9001(2008),ISO 14001 ,OHAS 18001 international quality system certificate, China pressure pipe safety registration certificate (AZ), European Union safety registration certificate (CE0036), and American Petroleum Institute Certificate (API 6D) and (API607) .

Industry Association Member

We are one of the member unit of China Valve Association as well as China Gas Association, member unit of first class supplying network of CNPC and member unit of fittings supplying network of State Power Corporation.

Related Products

More items about orbit ball valve

We Have The Best Solutions for Your Business

EDVC VALVE CO.,LTD.is a specialized in valve manufacturing enterprise with more than 15 years of history.We main produce Top Entry Ball Valve, Fully Welded Ball Valve, Arc Valve, Aluminum Bronze Valve, Automatic Recirculation Valve, Orbit Ball Valve, Safety Valve, Globe Valve, Tilting Disc Check Valve and Rising Stem Ball Valve etc.

The products have been exported to Austria, France, Germany, United Kingdom ,America, Middle East and Asia, Africa . areas and countries. Moreover, the products are widely used in the fields of oil & gas, Oil refinery, Petrochemical,power station ,Sewage treatment, pharmacy, Paper mills, pipeline industry , mining industry , chemical industry and environmental protection.

We are a professional manufacturer of valves in China, with the aim of "providing the first class products and services". On behalf of all of the members at EDVC Valve, we thank you for the opportunity to earn your business.

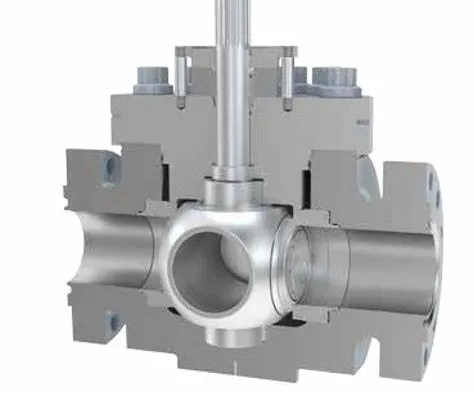

Orbital Ball Valve | Fixed Ball Valve

The ball of the ball valve is fixed and does not move after being pressed. The fixed ball valve is equipped with a floating valve seat. After the pressure of the medium, the valve seat moves, so that the sealing ring is pressed tightly on the ball to ensure sealing. Bearings are usually installed on the upper and lower shafts of the sphere, and the operating torque is small, which is suitable for high-pressure and large-diameter valves. In order to reduce the operating torque of the ball valve and increase the reliability of the seal, oil-sealed ball valves have appeared in recent years. Special lubricants are injected between the sealing surfaces to form an oil film, which enhances the sealing performance and reduces the operating torque. , It is more suitable for high-pressure and large-caliber ball valves.

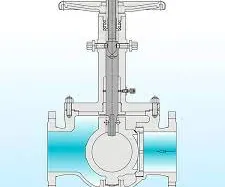

Orbital Ball Valve | Floating Ball Valve

The ball of the ball valve is floating. Under the action of the medium pressure, the ball can produce a certain displacement and press tightly on the sealing surface of the outlet end to ensure that the outlet end is sealed. The floating ball valve has a simple structure and good sealing performance, but the load of the sphere bearing the working medium is all transmitted to the outlet sealing ring, so it is necessary to consider whether the sealing ring material can withstand the working load of the sphere medium. This structure is widely used in medium and low pressure ball valves.

Orbital ball valve product features

1. There is no friction when opening and closing. This function completely solves the problem of traditional valve sealing due to the mutual influence between the sealing surfaces

2. The top-mounted structure can directly check and copy the door installed on the pipeline online to successfully reduce device parking and reduce production costs

3. Single valve seat design. Eliminates the problem that the medium in the valve cavity affects the safety of use due to abnormal pressure increase

4. Low torque design. The valve stem with a special structure design can be easily opened and closed with only a small handwheel valve

5. Wedge-shaped sealing structure. The valve is sealed by pressing the ball wedge to the valve seat by the mechanical force provided by the valve shaft. The sealing performance of the valve is not affected by changes in pipeline pressure difference, and the sealing performance is reliably guaranteed under various working conditions

6. Self-cleaning structure of the sealing surface. When the ball is tilted away from the valve seat, the fluid in the pipeline will pass evenly through 360° along the sealing surface of the ball. It not only eliminates the local scouring of the valve seat by the high-speed fluid, but also washes away the accumulation on the sealing surface to achieve the purpose of self-cleaning.

Orbital Ball Valve | Elastic Ball Valve

The ball of the ball valve is elastic. Both the ball and the valve seat sealing ring are made of metal materials, and the sealing specific pressure is very large. The pressure of the medium itself cannot meet the sealing requirements, and external force must be applied. This valve is suitable for high temperature and high pressure media. The elastic sphere is made by opening an elastic groove on the lower end of the inner wall of the sphere to obtain elasticity. When closing the passage, use the wedge-shaped head of the valve stem to expand the ball and press the valve seat to seal. Loosen the wedge-shaped head before rotating the sphere, and the sphere will return to its original shape, so that there is a small gap between the sphere and the valve seat, which can reduce the friction of the sealing surface and the operating torque. .

Frequently Asked Question

Do you have any question?

Even though ball valves aren’t the best device to control flow, they are still commonly used because of their cost effectiveness. You can get away with using a ball valve in an application that doesn’t require precise adjustability and control.

ORBIT rising stem ball valve's unique tilt-and-turn design reduces seal rubbing and delivers reliable performance.Every ORBIT rising stem ball valve incorporates a proven tilt-and-turn operation that eliminates seal rubbing, which is the primary cause of valve failure.

When an ORBIT valve begins to open, the core tilts away from the seat and line flow passes uniformly around the core face. This eliminates the localized high-velocity flow that typically creates uneven seat wear in ordinary ball, gate and plug valves. The core then rotates to the fully open position