Plus type fully equipped

CNC machine tools ,large vertical lathes, drill press, milling lathe grinding machine , Welding machine , separate metal working workshops and many general machine tool etc.

Multiple tests

Material analysis, PMI Material analysis. Chemical analysis. Low temperature test, Tensile Test ,Impact test, Hardness test. Wall thickness test, roughness test. Torque test. NDT Inspection (MT,PT,UT,RT). HIC test ,SSC test . Intercrystalline corrosion Test ,Uniform corrosion Test.

Passed ISO certification

The company is the first one to pass ISO 9001(2008),ISO 14001 ,OHAS 18001 international quality system certificate, China pressure pipe safety registration certificate (AZ), European Union safety registration certificate (CE0036), and American Petroleum Institute Certificate (API 6D) and (API607) .

Industry Association Member

We are one of the member unit of China Valve Association as well as China Gas Association, member unit of first class supplying network of CNPC and member unit of fittings supplying network of State Power Corporation.

Related Products

More items about orbit plug valve

We Have The Best Solutions for Your Business

EDVC VALVE CO.,LTD.is a specialized in valve manufacturing enterprise with more than 15 years of history.We main produce Top Entry Ball Valve, Fully Welded Ball Valve, Arc Valve, Aluminum Bronze Valve, Automatic Recirculation Valve, Orbit Ball Valve, Safety Valve, Globe Valve, Tilting Disc Check Valve and Rising Stem Ball Valve etc.

The products have been exported to Austria, France, Germany, United Kingdom ,America, Middle East and Asia, Africa . areas and countries. Moreover, the products are widely used in the fields of oil & gas, Oil refinery, Petrochemical,power station ,Sewage treatment, pharmacy, Paper mills, pipeline industry , mining industry , chemical industry and environmental protection.

We are a professional manufacturer of valves in China, with the aim of "providing the first class products and services". On behalf of all of the members at EDVC Valve, we thank you for the opportunity to earn your business.

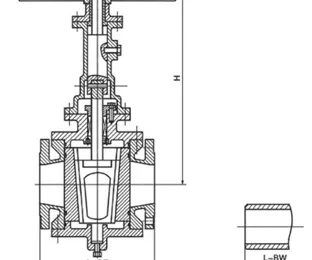

Orbital cock integral casting structure

Integral cock structure The cock of the orbital cock valve adopts an integral casting structure. The cock is integrated with the upper and lower shafts. When one-way compression is applied, the upper and lower shafts have sufficient rigidity, strength and bending resistance. The upper and lower shafts of the cock and the bottom cover and the valve cover are equipped with bearings. The machining accuracy and the hardness of the bearing ensure the accurate positioning of the upper and lower shafts, and prevent the upper and lower shafts from friction and wear caused by the pressure of the medium. , Reduced friction.

Application of orbital plug valve

Orbital cock valves are mainly used in the metering system, metering calibration system, multi-branch pipe mixed transportation system, tank root partition, aviation fuel storage and transportation, airport fuel plugs, frequently operated feeding and unloading systems, etc. In working condition. The medium is aviation kerosene, light oil, natural gas, liquefied gas, pipeline gas and other pipelines, as an ideal device for cutting off the medium.

Unique L-shaped groove structure of orbital plug valve

The operating mechanism of the valve and the operating mechanism (screw sleeve) of the self-locking orbital plug valve adopt a unique L-shaped groove structure. Separate the axial linear movement of the cock from the 90° rotation movement, which makes the valve operation flexible and light. The gear transmission mechanism used is self-locking, and the trapezoidal thread is a heavy-duty trapezoidal thread, which can bear a greater load.

Double sealing structure of middle flange

Orbital plug valves are mostly used for aviation kerosene, natural gas, liquefied petroleum gas, refined oil, etc. Because aviation kerosene and other media have strong permeability and are flammable and explosive, in order to prevent external leakage of the medium, they are used at the middle flange. Double sealing structure with O-ring and spiral wound gasket

Frequently Asked Question

Do you have any question?

Usually available in cylindrical or conical shapes, plug valves are quarter-turn manual motion valves used for stopping or starting the flow of fluid. They offer on-off, diverting, as well as basic moderate throttling services.

Plug valves offer better performance in the term of cutting than ball valves, but that doesn't show obviously. The sealing surface of the plug valve is much larger than the ball valve and supplies a better sealing effect, but a greater torque and small diameter.

When an ORBIT valve begins to open, the core tilts away from the seat and line flow passes uniformly around the core face. This eliminates the localized high-velocity flow that typically creates uneven seat wear in ordinary ball, gate and plug valves. The core then rotates to the fully open position.